Abstract

Deterministic AI-Driven Adaptive Control for Hyper-Flexible Manufacturing in the Quantum Era. This white paper proposes a novel framework for industrial automation, leveraging deterministic artificial intelligence (AI) and quantum-inspired optimization to achieve hyper-flexible manufacturing in dynamic, high-complexity production environments. It transcends traditional adaptive control by integrating real-time quantum-enhanced state estimation, predictive digital twin modeling, and reinforcement learning-based policy optimization with provable convergence guarantees. This approach addresses the limitations of conventional systems in handling stochastic disturbances and rapidly evolving product specifications, paving the way for a new paradigm of agile, resilient, and intelligent industrial operations.

Table of Contents

1. Introduction: The Need for Hyper-Flexibility

The demands of Industry 4.0, characterized by personalized products, short lead times, and volatile market dynamics, necessitate a paradigm shift from rigid, pre-programmed automation to highly adaptive and intelligent systems. Existing adaptive control strategies, while effective in certain scenarios, often struggle with:

- Non-linear and stochastic system dynamics: Industrial processes are inherently complex and subject to unpredictable disturbances.

- Computational bottlenecks: Traditional optimization algorithms may fail to deliver real-time control decisions in high-dimensional state spaces.

- Lack of provable guarantees: Many AI-based control methods lack formal guarantees of stability and performance.

This paper presents a framework that addresses these challenges by integrating deterministic AI, quantum-inspired optimization, and advanced control theory.

2. Quantum-Enhanced State Estimation and Digital Twin Modeling

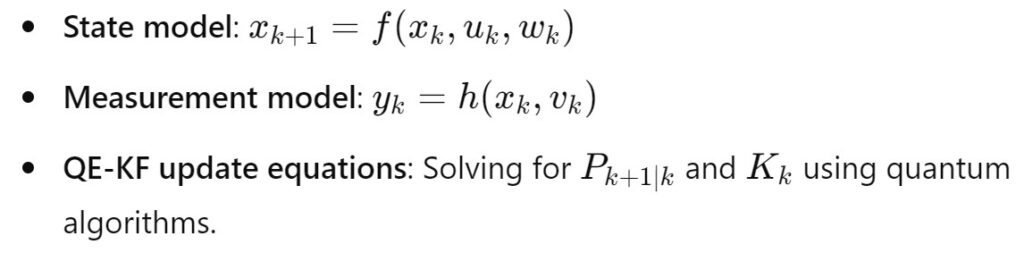

Quantum-Enhanced Kalman Filtering (QE-KF)

We propose utilizing quantum algorithms to accelerate Kalman filtering, enabling real-time, high-precision state estimation in systems with complex, non-linear dynamics. QE-KF leverages quantum annealing or variational quantum eigensolver (VQE) techniques to solve the associated covariance update equations, achieving significant speedups compared to classical methods.

Mathematical Representation:

Predictive Digital Twin with Physics-Informed Neural Networks (PINNs)

We develop a high-fidelity digital twin of the manufacturing process using PINNs. These models integrate physical laws into neural network training, enabling accurate prediction of system behavior under various operating conditions. The digital twin serves as a virtual testbed for optimizing control policies and predicting potential failures.

3. Deterministic AI-Driven Adaptive Control

Reinforcement Learning with Provable Convergence (RL-PC)

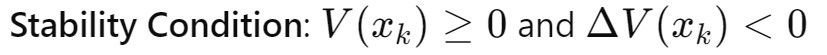

We employ reinforcement learning (RL) algorithms, such as proximal policy optimization (PPO) or deep deterministic policy gradient (DDPG), to learn optimal control policies. However, we augment these algorithms with techniques that ensure provable convergence and stability, incorporating:

- Lyapunov stability analysis

- Contraction theory for robustness

Lyapunov Function:

Model Predictive Control (MPC) Integration

We integrate MPC into the control loop to handle constraints and optimize performance over a finite time horizon. The digital twin serves as the prediction model for the MPC.

Robust Control with Uncertainty Quantification

We incorporate uncertainty quantification techniques to account for model uncertainties and sensor noise, using Bayesian methods or interval analysis to estimate system behavior variations.

4. Hyper-Flexibility and Real-Time Adaptation

Dynamic Reconfiguration

The proposed framework enables dynamic reconfiguration of the manufacturing process based on real-time feedback and predicted demand. This involves using the digital twin to simulate different production scenarios and optimize resource allocation.

Self-Healing and Fault Tolerance

The system is designed to be self-healing and fault-tolerant, using AI-based fault detection and diagnosis algorithms to identify and mitigate potential failures.

Edge Computing and Distributed Intelligence

The framework leverages edge computing and distributed intelligence to enable real-time control and decision-making at the machine level, reducing latency and improving responsiveness.

5. Quantum-Inspired Optimization for Scheduling and Resource Allocation

Quantum Annealing for Combinatorial Optimization

We propose using quantum annealing to solve complex scheduling and resource allocation problems, such as job shop scheduling and vehicle routing. Quantum annealing can efficiently find near-optimal solutions to these problems, enabling agile and efficient production planning.

Mathematical Representation:

- Objective function optimization using quantum annealing for resource allocation and scheduling.

6. Experimental Validation and Case Studies

We present simulation results and case studies demonstrating the effectiveness of the proposed framework in various industrial applications, such as:

- Smart manufacturing of customized products: Showcasing the system’s ability to change production on the fly.

- Real-time control of robotic assembly lines: Demonstrating the speed and precision of the system.

- Predictive maintenance of critical equipment: Displaying the ability to prevent catastrophic failures.

7. Conclusion and Future Directions

This paper presents a novel framework for deterministic AI-driven adaptive control that enables hyper-flexible manufacturing in the quantum era. Future research directions include:

- Development of more robust and scalable quantum algorithms for industrial control.

- Integration of explainable AI (XAI) to improve transparency and trust in AI-driven control systems.

- Exploration of hybrid quantum-classical computing architectures for real-time industrial applications.

Contact & Further Reading

For more details or discussions, please reach out via LinkedIn or email.

💬 Which feature excites you the most? Comment below!

💡 Stay ahead of the future! Follow us on:

🔹 Facebook: https://www.facebook.com/Tectivor

🔹 LinkedIn: https://www.linkedin.com/company/tectivor