Table of Contents

Abstract

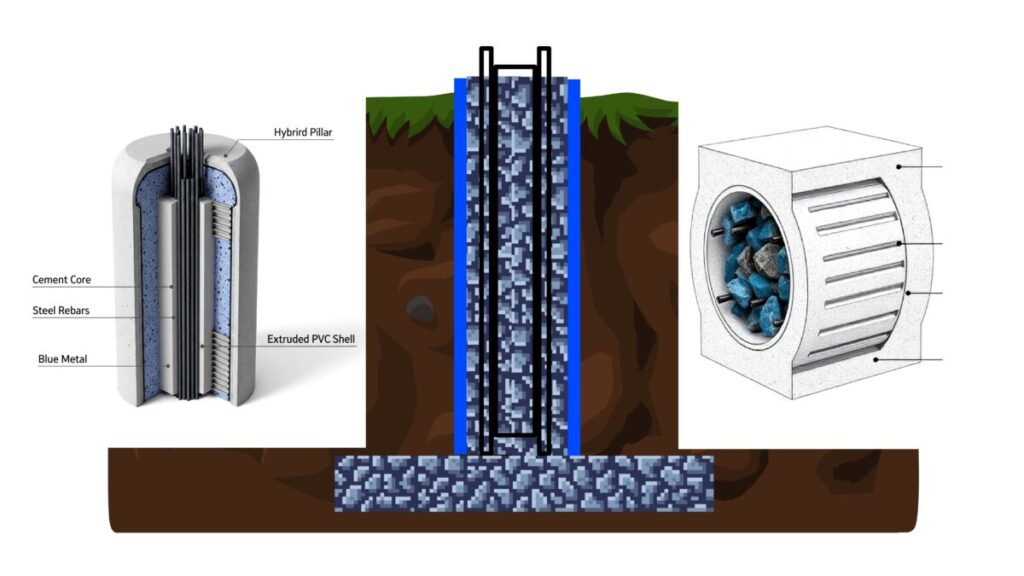

Hybrid Foundation Pillars – This paper proposes a novel hybrid construction component: extruded PVC hollow shells used as permanent outer forms filled with cement to create waterproof, load-bearing pillars or foundation elements. This design offers improved water resistance, reduced labor in formwork, and potential for modular, scalable production. The concept is especially suited for wet-zone foundations and underground structural elements.

Optional reinforcement with steel or fiber rods enhances structural integrity, particularly in demanding environments.

Introduction

Water ingress and concrete decay are long-standing issues in construction, especially in wet environments such as basements, foundations, or coastal structures. Traditional reinforced concrete pillars require labor-intensive formwork, careful curing, and are still vulnerable to water-related issues if not sealed correctly. Additionally, plastic and tar-based mixtures have been explored but offer inconsistent bonding and structural performance. This paper proposes a simple yet powerful idea: using extruded PVC as a permanent form and outer waterproof shell for cement-based structural cores.

The integrity of foundation structures is critical in any building project, particularly in wet or high-moisture environments where water ingress can lead to long-term structural damage. Traditional reinforced concrete pillars rely heavily on steel rebars, which, despite their strength, are prone to corrosion over time.

This paper introduces an innovative approach to foundation construction using hybrid pillars composed of extruded PVC shells filled with cement—a solution designed for waterproofing, cost-efficiency, and durability. In addition, we explore modern alternatives to conventional steel reinforcement, such as Basalt Fiber Reinforced Polymer (BFRP) and Carbon Fiber Reinforced Polymer (CFRP) rebars, to further enhance the longevity and performance of these hybrid structures. This concept presents a new direction for engineers, architects, and builders aiming to improve foundation performance while minimizing maintenance and material degradation.

The Concept

The proposed system involves the use of extruded PVC shells or hollow boxes as permanent outer casings for structural foundation pillars. These PVC casings are fabricated through standard extrusion techniques, allowing for consistent quality and scalable manufacturing. Once installed in position—whether vertically for pillars or horizontally for beams—the hollow interior is filled with cement, forming a solid, load-bearing core.

To enhance structural integrity, the cement core can be optionally reinforced using conventional steel rebars or modern alternatives such as Basalt Fiber Reinforced Polymer (BFRP) or Carbon Fiber Reinforced Polymer (CFRP) rods. These corrosion-resistant materials ensure long-term durability even in wet or chemically aggressive environments.

The PVC shell remains in place permanently, serving multiple functional roles:

- Waterproof barrier to prevent water seepage into the cement core

- Structural formwork, eliminating the need for temporary shuttering

- Chemical and thermal insulation, offering protection in aggressive or variable climate zones

- Shape retention, ensuring dimensional accuracy and reducing post-cure cracking

This hybrid pillar design simplifies on-site construction, reduces material wastage, and enhances the overall lifespan of foundations, particularly in areas prone to moisture infiltration.

Key Benefits

- Waterproofing: PVC acts as a moisture barrier.

- Permanent formwork: No removal required, saving time and reducing labor.

- Lightweight & modular: Easier to transport and install.

- Uniform design: Factory production allows standard sizes and clean finish.

- Scalable & low-cost: Can be manufactured locally using existing PVC extrusion techniques.

- Durability: PVC resists corrosion, rot, and insect attack.

Comparison with Traditional RCC Pillars

| Feature | RCC Pillar | PVC + Cement Hybrid Pillar |

|---|---|---|

| Waterproofing | Requires external treatment | Inherent via PVC shell |

| Formwork | Needs wooden/metal formwork | PVC shell acts as formwork |

| Labor | More intensive | Reduced |

| Durability in wet zones | Medium (with treatment) | High (inherent) |

| Customization | Low | High (modular design possible) |

Reinforcement Materials Comparison Table

| Feature | Steel Rebar | CFRP (Carbon Fiber) | BFRP (Basalt Fiber) |

|---|---|---|---|

| Tensile Strength | High | Very High | High |

| Corrosion Resistance | Poor (even with coating) | Excellent | Excellent |

| Weight | Heavy | Ultra-Light | Light |

| Cost | Low (most affordable) | Very High | Moderate |

| Thermal Resistance | Moderate | High | Very High |

| Electrical Conductivity | Conductive | Conductive | Non-conductive |

| Ductility (Bendable) | Good | Brittle | Brittle |

| Bond with Cement | Excellent | Good (needs special surface treatment) | Good (ribbed types available) |

| Availability | Widely Available | Limited | Limited |

| Ease of Use | Easy for all construction teams | Needs trained handling | Needs trained handling |

| Sustainability | Energy-intensive production | High, but long-lasting | Made from natural basalt rock |

| Ideal Use Cases | General construction | Bridges, aerospace, critical infrastructure | Marine, coastal, and chemical environments |

Summary:

- Steel is cheap and ductile, but corrodes.

- CFRP is ultra-strong and durable but very expensive and brittle.

- BFRP offers a balanced, corrosion-proof alternative with good strength and cost-effectiveness — ideal for waterproof or marine environments, like your PVC-cement hybrid pillars.

Material Considerations

- Bonding: Cement does not bond chemically with PVC; therefore, PVC shells should include internal ribs, roughened surfaces, or bonding agents to allow mechanical locking.

- Reinforcement: Steel rebars or fiber can be placed inside before cement pour for structural strength.

- UV Stability: If exposed to sunlight, UV-stable or coated PVC should be used.

- Fire Safety: Use fire-retardant PVC in above-ground applications.

Applications

- Foundations in wet or marshy areas

- Basements and underground columns

- Septic tank structures

- Coastal structures

- Temporary or semi-permanent construction in flood-prone regions

Limitations and Further Research

- Structural behavior of PVC shell over decades

- Fire performance under high-load conditions

- Optimal PVC wall thickness for balance of strength and cost

- Thermal expansion differences between cement and PVC

- Bonding techniques for better integration between materials

Conclusion

This hybrid construction method offers a practical, affordable, and scalable solution for creating waterproof load-bearing pillars using widely available materials. It has the potential to reduce cost, labor, and material waste while enhancing durability in wet conditions. We share this idea as a seed for innovation and welcome further exploration, testing, and development by researchers, builders, and engineers.

Author’s Note

This concept arose early one morning from a simple observation: waterproofing and load-bearing needs could be merged into one elegant component. Rather than relying on separate treatments or materials, this approach uses permanent extruded PVC shells to combine function, simplicity, and sustainability. This white paper is published publicly to invite others to explore, build upon, or enhance the idea in the spirit of open development.

💡 Stay ahead of the future! Follow us on:

Facebook | LinkedIn